What We Do

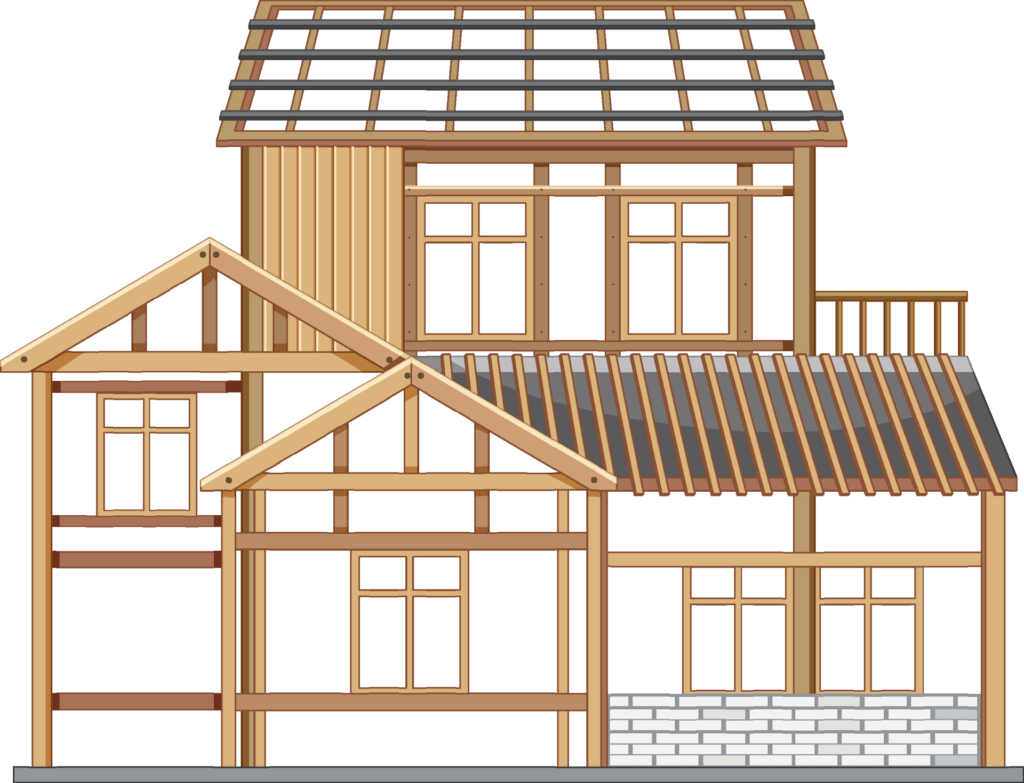

TimberTight supply the complete structural frame - walls, floor, and roof.

This timber frame structure replaces the typical concrete block inner leaf used in traditional construction. To learn more about the benefits of timber frame, click here.

We have a range of systems available to meet your requirements. If you can’t find what you’re looking for, get in touch.

Wall Systems

The timber frame wall structure replaces the concrete block inner leaf used in traditional construction.

Floor Systems

TimberTight use engineered joist systems to create solid, durable first and second floor structural decks.

Roof Systems

We offer truss, attic, I-joist, and metal web joist roof systems for flat or pitched roofs.

Discover

The benefits of offsite manufacturing

Our quality controlled manufacturing process ensures the highest accuracy timber frame.

Our skilled factory operatives work from drawings created from the three-dimensional models to craft wall panels, floors, and roof structures to tight manufacturing tolerances. Factory production guarantees a quality accurate build on site.

TimberTight’s Structural Timber Association Gold status and ISO certification ensures manufacture to audited quality standards. Only the best certified materials are used in TimberTight’s manufacture process!

Design

Our in-depth bespoke design process

Months before work on site, TimberTight undertake an in-depth bespoke design service for every project. This is key to our success in delivering the very best possible product to site for our clients.

TimberTight’s expertise in architecture, building regulations, mechanical services, thermal insulation, and much more enables the elimination of many problems before work starts on site. It’s the reason why we’re such rigorous planners!

During discussion with the client, we work with architects and our engineers to produce a factory-manufactured structural frame. This is split into transportable sections, and fixed together on site, in accordance with the project’s engineering specification.

TimberTight’s designers engineer, draw, and build three-dimensional computer models of the timber frame in specialist software. The three-dimensional models highlight project aspects which may be unclear on 2D plans.

Have a look at our technical section for more information.

Deliver

On site timber frame erection

TimberTight use a platform construction method to erect timber frame structures.

You can be offered a supply only option during quotation, but we would advocate our highly experienced erection teams. They will use TimberTight’s construction plans to fix the timber frame structure accurately and robustly to our engineer’s specifications.

Wall panels, floor cassettes, and roof trusses are offloaded and erected with cranes.

The scaffold is erected in accordance with TimberTight’s requirements prior to timber frame works starting.